Installation of a lighting control system using power line communication in a detention center in the USA

Power line communication, an intelligent solution for controlling LED luminaires where wireless communication is not an option.

The manager of this detention center wanted to install LED luminaires on the exterior of his detention center, mainly for the quality of the lighting and the energy savings. In order to take full advantage of this type of lighting, a control system was required.

For security reasons, control by wireless communication (Wi-Fi, radio frequency or other) was not possible, as these technologies are more susceptible to remote cyber-attacks. Hacking could allow criminals to turn off the lights to bring cell phones, drugs and weapons into the prisoners’ yard. Such intrusions could potentially put the lives of staff and other prisoners at risk.

For the same reasons, but also for cost motivations, the managers didn’t have to install more than a kilometer of control wiring. In fact, the TLACS-A solution from Nyx Hemera Technologies, which was installed, uses power line communication (communicates over the electrical wiring already supplying the luminaires).

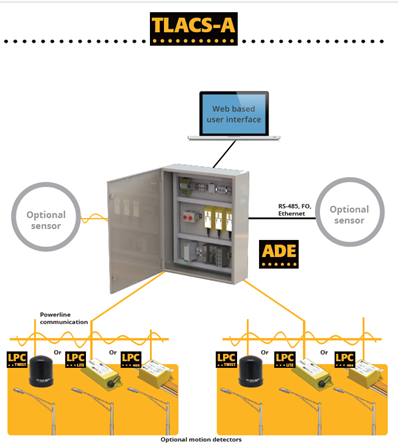

TLACS-A

Description

The TLACS-A is a turnkey solution for controlling and dimming luminaires on outdoor sites requiring supervision, energy management and/or enhanced safety.

With individual lighting monitoring and control, the TLACS-A is the perfect solution for detention centers, power plants, parking lots, secure areas or any other sensitive site where lighting needs to be well managed. Easy to use, it provides local or remote access for lighting control and supervision.

Depending on the type of application and luminaires, TLACS-A can use LPC Twist for outdoor luminaires with receptacles supporting ANSI C 136.41, or LPC 480 Standard, which is installed in luminaires where this is possible.

Figure 2: PLA Tool interface

The ADE (Area Dimming Enclosure) is a control cabinet that includes all the equipment needed for intelligent, dynamic decision support for lighting system management. The ADE collects information from each of the local controllers (LPCs), control system configuration and management. Information is accessed via a dedicated interface. A database containing operation history is available as an option.

The lighting level request can be determined from a pre-set schedule, or from data collected by just about any sensor that can have an impact on the required lighting level. (a motion detector, photocell, luminance meter or illuminance meter).

Installed in the luminaire, the LPC controls and supervises the luminaire drivers, as well as controlling (ON-OFF) and dimming them according to the lighting level required.

LPC calculates hours of use and reports luminaire status and electrical parameters to ADE for diagnostic purposes.

Different LPC versions can be integrated into TLACS-A (LPC Twist, LPC Lite or the standard LPC 480) for different applications, infrastructures and luminaires.

For the detention center project, Nyx Hemera Technologies installed the LPC-Twist, which has the following features:

Figure 2: LPC Twist Local Controller

– Universal 7-pin interface socket (ANSI C136.41)

– Photocell for local operation

– Optimized lighting dimming

– Integrated filter to eliminate mains noise

– Automatic internal luminaire temperature report

– Firmware update via wireless communication network

– Report on luminaire electrical parameters:

- Voltage

- Power factor

- Power consumption (generic accuracy 2%, other options available)

- Current

- Luminaire status

- Fail safe mode using photocell

– Acts as a dynamic repeater

– Available for 110 – 480 VAC networks

– UL 916 certified (Standard for energy management equipment)

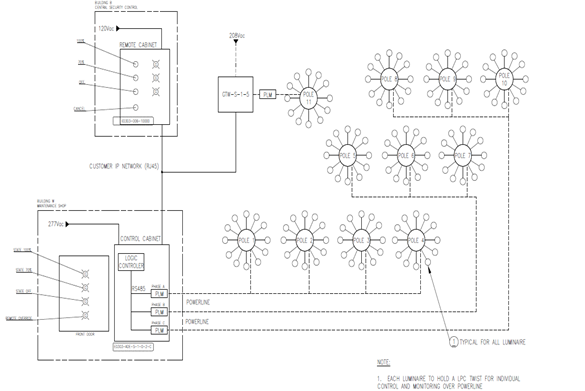

Figure 3: Installation of 12 luminaires per pole

System architecture

The luminaires are installed on 12 poles, each housing 12 luminaires. Each luminaire is controlled by an LPC Twist installed on the receptacle (ANSI C136.41).

The system is supervised by an internal software application.

A control box is remotely accessible from the monitoring station, so that staff can turn all the lights on or off in a matter of seconds in the event of an emergency.

Figure 4: System architecture

System performance

Lighting mode

The lighting is regulated to 70% of its capacity at night, and the luminaires are switched off during the day. Day and night, the lighting can be controlled manually by a switch.

n the event of a communication problem, a photocell built into the LPC-Twist will take over, requesting a lighting level between 70% and 100% at night, and 0% during the day.

Lighting regime changes are made in broadcast mode in a matter of seconds for all luminaires installed over more than 1050 meters (3500 feet).

User interface

A custom-designed user interface for the detention center allows:

– Different levels of access (administrator, user, etc.)

– System configuration

– Lighting system overview by

- Group

- Zone

- Each luminaire (voltage, power factor, current, luminaire status)

– Alarm visualization

Conclusion

The installation of an intelligent power line lighting control system enabled the managers of the detention center to reduce installation time and expense when upgrading its lighting system with LED luminaires. As a result, they were able to avoid installing over a kilometer of control wiring.

The use of carrier current will also limit the risks of intrusion to control the lighting system. Indeed, any change in lighting levels must be made on site, either physically, in the control cabinet (ADE) or via the user interface at the detention center’s supervision and control station.

In addition to reducing energy consumption, TLACS-A will help reduce lighting system maintenance costs by monitoring luminaire status via the user interface. Ultimately, this supervision will enable the creation of a preventive maintenance plan.

The benefits of using such a system for the detention center could be applicable to any site where wireless control systems (Wi-Fi, RF or other) cannot be installed, and where it is impossible to install control wiring.