THERE IS MUCH MORE TO AN INTELLIGENT LIGHTING CONTROL SYSTEM THAN JUST DIMMING…

A tunnel operator who installed the TLACS solution (Nyx Hemera Technologies’ intelligent luminaire control system) sent in a video of his tunnel where 6 luminaires could be seen flashing randomly. As a result, the operator placed a service call to Nyx Hemera Technologies’ technical department at 1:21 p.m. using Microsoft Teams. Using remote access granted by the operator, the Nyx Hemera Technologies team took remote control of the TLACS lighting SCADA. During this session, the technical team confirmed that there were 14 luminaires in alarm in two specific areas of the tunnel. Using electrical parameters provided by the LPC (Local Product Controller), which is installed in the luminaire and uses powerline communication to communicate with TLACS’ main controller, the LCC, the Nyx team was able to remotely investigate and discover that a voltage drop below the luminaire’s driver threshold was causing the flickering. The call ended at 2:45 pm. Once this information was relayed to the on-site team, the tunnel was closed for 45 minutes to resolve the problem by replacing a power terminal block located in one of the electrical distribution junction boxes. Lighting and traffic then returned to normal.

A Friday 13th that ends well!

Teamwork is key

On August 13, 2021, a tunnel operator using Nyx Hemera Technologies’ Powerline Lighting Control System (TLACS) contacted Nyx’s technical support team with a problematic situation that appeared to be related to the lighting control system installed in their tunnel. The operator sent a short video for observation.

Upon viewing the video, Nyx’s technical support team could see at least 6 lights flashing randomly in an isolated portion of the left tunnel wall from the drivers’ direction of travel.

Figure 1 shows two screenshots of the video showing the observed anomaly.

Knowing that any interruption in a tunnel is costly and that such a problem must be dealt with quickly, a Microsoft Teams call was initiated with the tunnel operator.

Figure 1 – Screenshot of the video provided by the operator

The communication tool

With the installation of a dedicated TLACS SCADA system, the operator shared his PC screen and the Nyx technical support team took control to access the PC hosting the TLACS SCADA system via a remote computer.

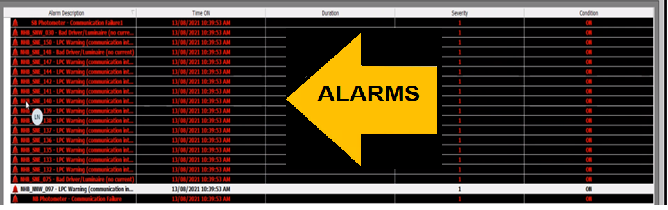

From the TLACS SCADA web application, they observed a total of 14 luminaires in alarm in the isolated area corresponding to the flashing luminaires in the southern interior transition areas of the tunnel.

Figure 2 – List of alarms in the tunnel TLACS-SCADA on August 13, 2021 at 1:21 p.m.

Remote diagnosis

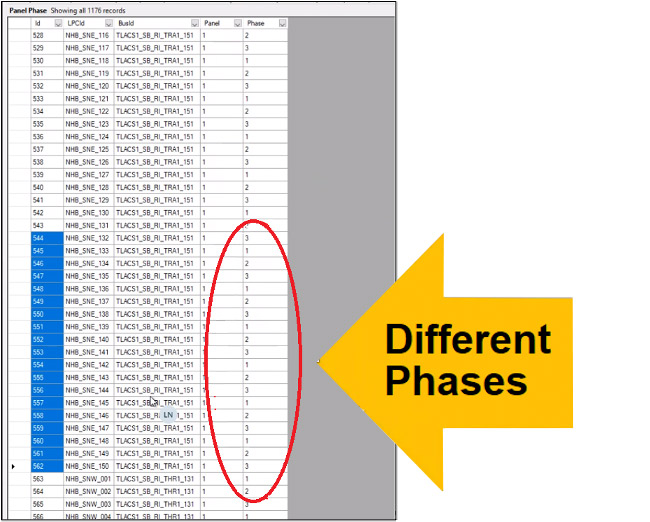

The first hypothesis was that the problem could be electrical and related to one of the different electrical phases associated with the affected fixtures. Using the TLACS Configuration Management Software (CMS) to find the phases associated with the 14 problematic fixtures, a possible problem on one of the phases was ruled out. The affected fixtures used the three different electrical phases available.

Figure 3 – Screenshot from Nyx Hemera’s Configuration Management Software (CMS) showing the phases used by the failed fixtures

We take a closer look at the fixtures

Back at the CMS, the Nyx technical support team performed a read of all the fixtures’ internal variables using the ‘Read Properties’ command to see the error message listed for each fixture. The 14 problematic fixtures were displaying the error message “LPC CANNOT REACH FIRST ROUTER” intermittently. This was a possible explanation for the flickering lights, but the cause of the miscommunication still needed to be investigated to confirm it.

Nyx’s technical support team suspected a hardware electrical problem. Using the ‘addressability’ of TLACS, the team initiated the repeater function of the LPC, where each unit repeats the signal to subsequent units on the power grid so that it can connect to faulty fixtures.

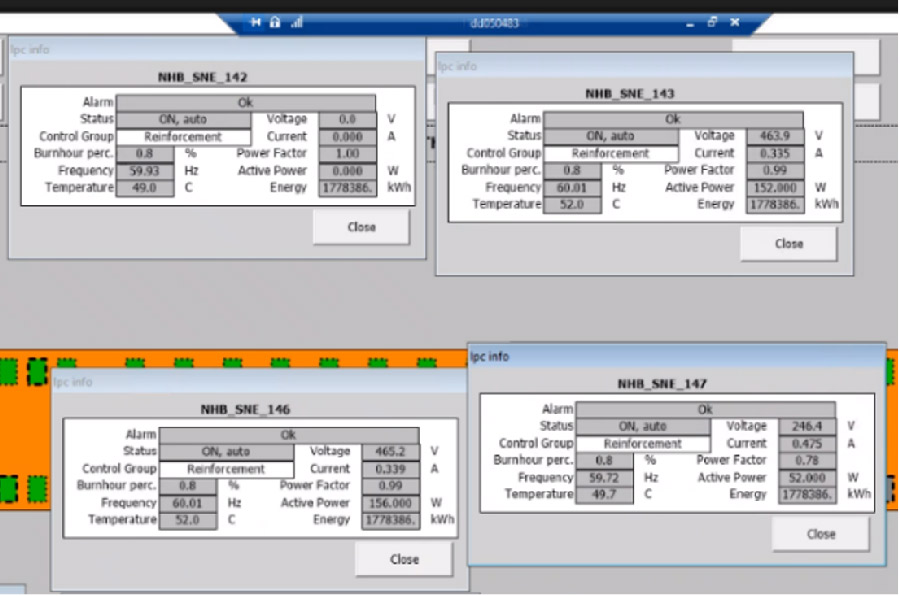

Returning to the TLACS SCADA web application, it was now possible to read the electrical parameters of the luminaires (voltage, power factor, power consumption, current and luminaire status) for each of them.

Figure 4- Electrical parameters of 4 of the 14 luminaires in alarm

With the system communicating on a 480 VAC power grid, the Nyx team noticed a low voltage level (well below 480 VAC) for the problematic LPCs, hinting at the suspected electrical problem that explains the random flickering of the LED lights observed in the tunnel. Indeed, when the voltage falls below the threshold of the LED driver, the LED turns off. Thus, if the voltage changes rapidly from one moment to the next, going from below to above the threshold, the LED will flash.

Use of the information collected

The call to the crews ended at 2:45 p.m. and the operator passed the information to his team on site to investigate the source of the electrical problem.

The next day, at 11:38 a.m., the onsite manager sent an email informing that the source of the electrical problem had been identified and resolved:

Use of the information collected

“We found the problem. We replaced the terminal block and the lights returned to their normal state. Closing time was 8:15pm and we exited the tunnel at 8:57pm. We returned to the north tower to examine the lighting controller for another 10 minutes to confirm there were no other problems.”

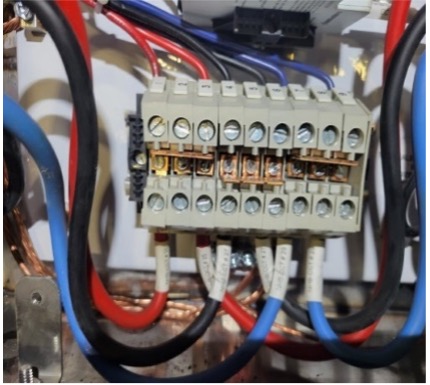

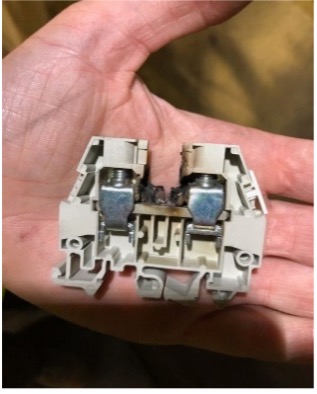

Figure 5- Junction box with defective terminal blocks

The communication problem was not with the TLACS lighting control system, but with a poor wire connection that caused the terminal block to heat up and burn out.

This certainly would not have been possible if the tunnel had been equipped with a hard-wired control system, which typically has an average of 6 connectors per luminaire, and the situation could have been even worse if no control system had been installed.

Figure 6 – Burned terminal block

As this event demonstrated, the powerline lighting control system reduces the amount of wiring and control equipment that must be installed in the tunnel. Overall, it is a much simpler system that offers control features that wired systems cannot and makes it easier to maintain and operate the lighting system.

CONCLUSION

In conclusion, the lighting control system was not the cause of the problem. This case demonstrates that intelligent lighting control systems are powerful tools for controlling but also for remotely monitoring the various electrical parameters of the luminaires. These allow for the remote diagnosis of communication and electrical problems typically encountered in tunnel lighting operations.